2-Phenylindole Technical Specs (CAS 948-65-2)

At Gotrays, we supply high-purity 2-Phenylindole designed to meet rigorous industrial standards for PVC stabilization and organic synthesis. Our product, identified by CAS 948-65-2, serves as a critical intermediate and heat stabilizer, ensuring consistent quality for downstream manufacturing. We prioritize precise chemical parameters to guarantee compatibility with Calcium/Zinc and Barium/Zinc stabilizer systems.

Chemical Properties & Specifications

Our 2-Phenylindole is manufactured to strict specifications, ensuring a minimum purity of 99.0%. The following table outlines the key technical data for our standard grade material:

| Property | Specification |

|---|---|

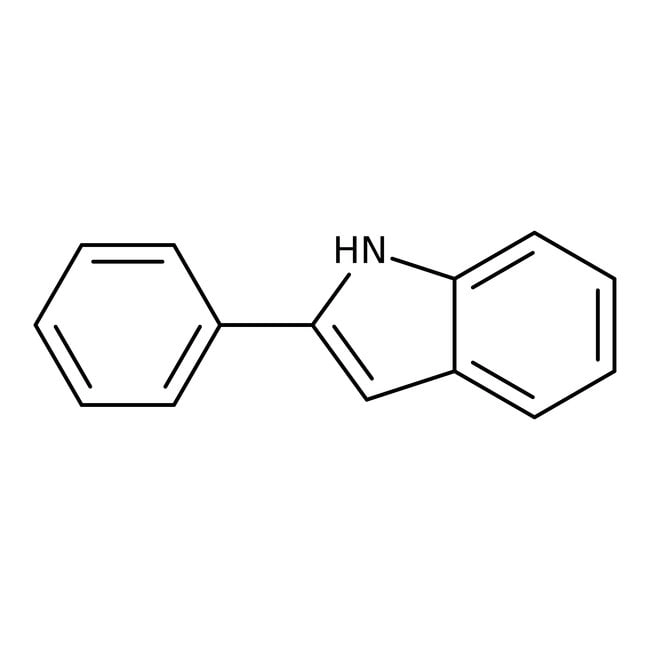

| Product Name | 2-Phenylindole (2-Phenyl-1H-indole) |

| CAS Number | 948-65-2 |

| Molecular Formula | C14H11N |

| Appearance | White to off-white crystalline powder |

| Assay (Purity) | ≥ 99.0% |

| Melting Point | 188°C – 191°C |

| Loss on Drying | ≤ 0.5% |

Solubility Profile

Understanding the solubility of C14H11N is essential for proper formulation in PVC processing and chemical synthesis. Our product exhibits the following solubility characteristics:

- Organic Solvents: Highly soluble in alcohol, ether, acetone, and benzene.

- Water: Insoluble.

This solubility profile allows for easy integration into solvent-based systems and effective dispersion within polymer matrices during processing.

Why Use 2-Phenylindole for PVC Stabilization?

When we talk about stabilizing PVC, 2-Phenylindole stands out as a critical component for modern formulations. We don’t just supply a chemical; we provide a solution that solves specific processing headaches. Here is why this PVC auxiliary stabilizer is essential for your production line.

Synergistic Power with Ca/Zn Stabilizers

The real magic happens when you pair this material with metallic soaps. It acts as a powerful Calcium Zinc stabilizer synergist. While Ca/Zn systems are environmentally friendly, they sometimes need a boost to match the performance of older systems. Adding 2-Phenylindole bridges that gap, significantly enhancing the overall stability of the compound. It also exhibits strong synergistic effects when used with Barium/Zinc and Cadmium/Zinc soap stabilizers.

Superior Anti-Yellowing Performance

Nobody wants discolored plastic. We know that maintaining the pristine look of the final product is non-negotiable. As a PVC anti-yellowing agent, 2-Phenylindole excels at:

- Excellent Initial Coloring: It prevents that immediate color shift during the early stages of heating.

- Long-Term Thermal Stability: It keeps the material stable throughout the processing cycle, preventing degradation over time.

Non-Toxic and Safe for Sensitive Applications

Safety regulations are getting tighter globally. Our product is SGS certified and meets strict non-toxic environmental requirements. This makes it an ideal choice for non-toxic PVC additives used in sensitive sectors where compliance is mandatory.

Crystal Clear Results

For manufacturers producing transparent films, sheets, or profiles, clarity is king. Because of its high purity (≥ 99.0%) and compatibility, it integrates smoothly into the matrix. It supports the production of clear PVC products without introducing haze, ensuring your transparent films stay truly transparent.

Where to Use This PVC Auxiliary Stabilizer

We supply 2-Phenylindole to industries requiring high-performance thermal stability without compromising safety. Its versatility makes it a go-to choice for manufacturers dealing with sensitive rigid PVC formulation and complex chemical synthesis. Because it works synergistically with Calcium/Zinc soaps, it is essential for modern, eco-friendly production lines.

Here is where our product delivers the most value:

- Rigid PVC Packaging & Pharma Blisters: Since our material is SGS certified and meets non-toxic standards, it is ideal for pharmaceutical blister packs and food-contact packaging. It maintains excellent transparency in films and sheets, preventing the yellowing often seen in lower-quality stabilizers.

- Construction Profiles & Pipes: For outdoor applications, this PVC auxiliary stabilizer enhances weatherability. It ensures long-term durability and thermal resistance in PVC profiles and pipes exposed to processing heat and environmental stress.

- Medical Grade Plastics: Safety is non-negotiable in healthcare. We recommend this additive for medical tubing and storage containers where non-toxic PVC additives are strictly required to ensure patient safety and product purity.

- Organic Synthesis Intermediate: Beyond plastics, it serves as a crucial organic synthesis intermediate. It is widely used in the chemical industry to synthesize specific dyes, fluorescent brighteners, and pharmaceutical compounds.

How It Works: The Chemistry Behind 2-Phenylindole Stability

Understanding the mechanism of 2-Phenylindole (CAS 948-65-2) is key to maximizing its potential in your formulations. We utilize this compound not just as a filler, but as an active thermal stability agent that tackles PVC degradation at the molecular level.

Here is the breakdown of how it protects your polymer chains:

- Reacting with Allyl Chloride: The primary function of this PVC auxiliary stabilizer is to stabilize the polymer backbone. It actively reacts with labile allyl chloride structures within the PVC chain. By replacing these unstable atoms, it stops the “zipper” degradation reaction that typically leads to material failure.

- Ca/Zn Soap Co-stabilizer Synergy: This product shines when used as a Calcium Zinc stabilizer synergist. It works hand-in-hand with metallic soaps (like Ca/Zn, Ba/Zn, or Cd/Zn). While the soaps neutralize acidic byproducts, 2-Phenylindole regenerates the active stabilizer components, significantly extending the long-term heat stability of the final product.

- Scavenging Free Radicals: During high-temperature processing, free radicals can wreak havoc on color and clarity. Our material acts as a scavenger, preventing the cross-linking and oxidation that cause yellowing. This ensures excellent initial coloring and maintains the high transparency required for rigid films and profiles.

Storage, Handling, and Safety Protocols

We prioritize the integrity of our chemical supplies to ensure they perform consistently in your production line. Proper handling is critical to maintaining the high purity and thermal stability of 2-Phenylindole from our warehouse to your facility.

Industrial Packaging Options

We offer robust packaging solutions designed to withstand global logistics and prevent contamination. Our standard options for CAS 948-65-2 include:

- 10kg, 20kg, and 25kg bags: Multi-layer Kraft paper bags or fiber drums that protect against moisture and physical damage.

- Sealed Liners: Inner liners ensure the white crystalline powder remains dry and free from impurities.

Storage Conditions for Maximum Shelf Life

To preserve the efficacy of this PVC heat stabilizer, strict environmental controls are necessary. When stored correctly, the product maintains a stable shelf life of up to 24 months.

- Environment: Store in a cool, dry, and well-ventilated area.

- Protection: Keep away from direct sunlight, heat sources, and strong oxidizers.

- Maintenance: Ensure containers are tightly closed immediately after use to prevent moisture absorption, which can affect the melting point (188℃ – 191℃).

Safety and Compliance (MSDS)

Although 2-Phenylindole is an SGS-certified non-toxic additive suitable for various PVC applications, standard industrial hygiene is required.

- PPE: Operators should wear dust masks, safety goggles, and gloves to avoid inhalation or skin contact with the powder.

- Documentation: We provide a comprehensive Material Safety Data Sheet (MSDS) with every shipment. This document details specific handling instructions and emergency measures to help you meet local safety and environmental regulations.

Why Source Your 2-Phenylindole From Gotrays?

At Gotrays, we understand that consistency is the backbone of your manufacturing process. We don’t just sell chemicals; we provide a stable foundation for your PVC heat stabilizer formulations. When you source CAS 948-65-2 from us, you are partnering with a team dedicated to keeping your production lines running smoothly without interruption.

We focus on three core value pillars for our global partners:

- ISO-Certified Consistency: We strictly control our manufacturing process to ensure every batch of 2-Phenylindole meets a purity of ≥ 99.0%. You get the same high-performance organic synthesis intermediate every time, minimizing the need for constant formulation adjustments.

- Reliable Global Supply Chain: Whether you need urgent air freight or planned bulk sea shipments, our logistics network handles it. We offer flexible delivery options to support just-in-time inventory strategies, ensuring you never face downtime due to material shortages.

- Expert Formulation Support: Our technical team knows how this PVC auxiliary stabilizer interacts with Calcium Zinc systems. We assist with dosage recommendations to help you achieve optimal thermal stability and cost-efficiency in your final products.

Trust Gotrays to deliver the quality and expertise your business deserves.

Common Questions About 2-Phenylindole

Recommended Dosage for Rigid PVC Formulations

Determining the right amount of 2-Phenylindole is critical for balancing cost and performance. Since this product works as a synergist alongside Calcium Zinc (Ca/Zn), Barium/Zinc, and Cadmium/Zinc soap stabilizers, the exact percentage can vary based on your specific rigid PVC formulation.

- Synergy Factor: Because it boosts the effectiveness of metallic soaps, you may be able to optimize your overall stabilizer package.

- Custom Advice: We recommend consulting with our technical team to define the precise dosage that delivers the best long-term thermal stability for your specific machinery and end-product requirements.

Suitability for Non-Toxic Standards

We understand that compliance is non-negotiable for global manufacturers. Our 2-Phenylindole is SGS certified and strictly adheres to non-toxic environmental requirements.

- Safety Profile: It is engineered to be a safe, effective PVC heat stabilizer for both rigid and soft applications.

- Compliance: The product’s non-toxic nature makes it a reliable choice for industries moving away from hazardous additives, ensuring your final products meet necessary safety benchmarks.

Process for Requesting Samples

We know you need to verify performance data—like melting point and purity—in your own facility. We make the sampling process simple so you can test the anti-yellowing capabilities and initial coloring benefits directly.

- Lab Testing: Contact us to request a sample batch for your R&D trials.

- Verification: This allows you to confirm the chemical’s compatibility with your existing PVC processing aids before scaling up to full production.

Reviews

There are no reviews yet.